A project to smartly reduce inspection time for prototype and short-run and cost at a critical bottleneck

- Market changes led to an increase in long-term production contracts in the space sector.

- The Lockheed Martin Space machine shop specialized in prototype “one-off” manufacturing and needed change to meet these new market demands.

- I developed a four phase plan to update procedures and technology in the machine shop. Phase 1 was implementing a sample inspection procedure.

- Six month after implementation I recorded a 50% increase in shop throughput while touch-labor hours remained constant.

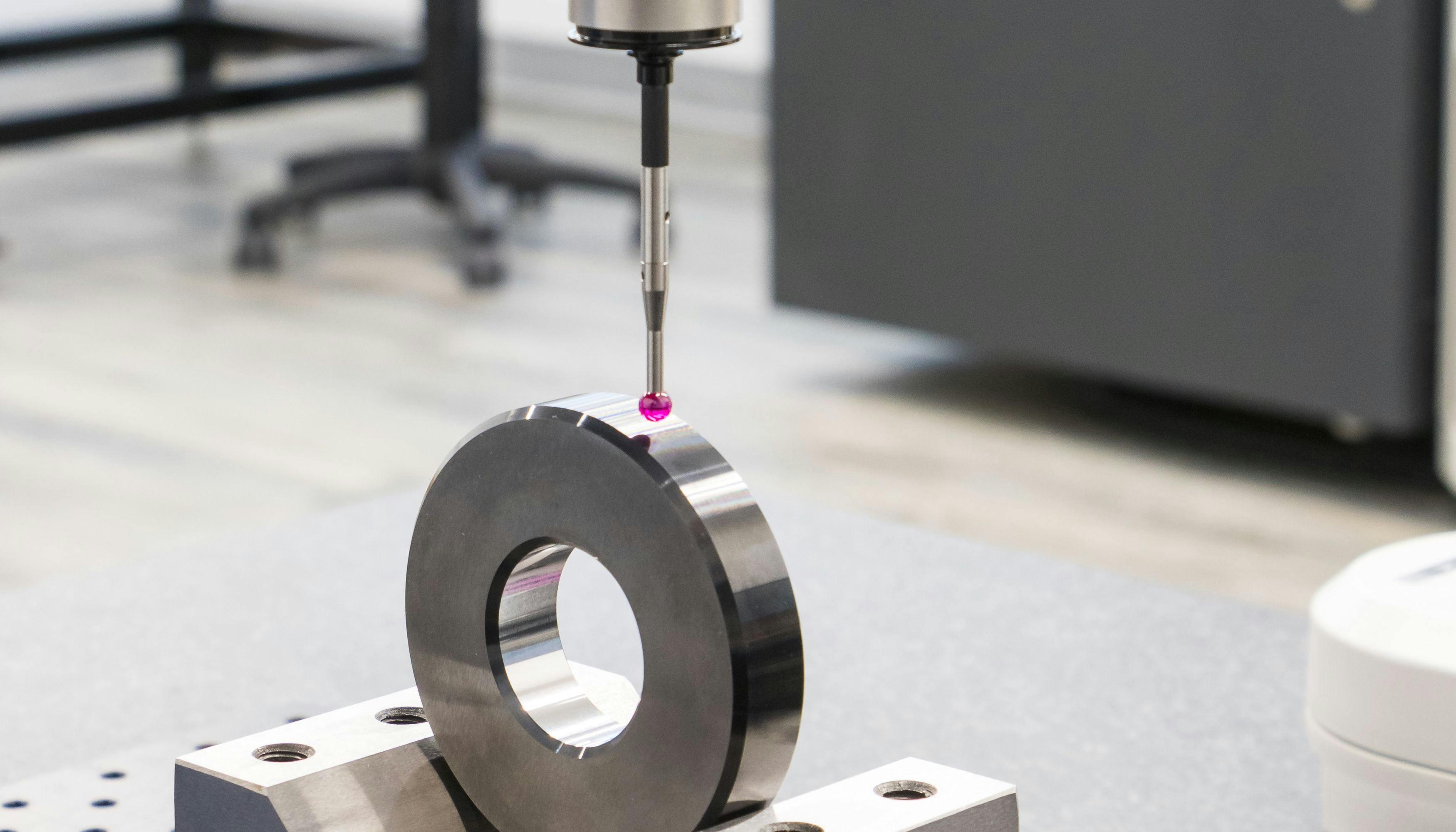

I implemented a sample inspection procedure in the Lockheed Martin Space prototype machine shop where we manufactured products for space applications. This was the first project in a four-phase plan to move to a hybrid prototype/production machining model to bring the shop in-line with market demands.

The commercial and defense space market had traditionally been comprised of one-off space vehicles. The advent of commercial space flight brought with it a portfolio of customers with long-term production contracts for many space vehicles.

I first noticed this trend in our machine shop while shadowing our quality assurance technicians. We started getting more orders for high batches of parts 10 or more and an increase in repeat orders. The inspectors were spending large amounts of time inspecting every drawing dimension for every machined part in batches that were sometimes 150 parts or more. We were following prototype processes for production product and our shop needed to change.

I researched industry standards on sample inspection, reviewed existing shop procedures and produced a general procedure that would guide our technicians and engineers through the process. I then invited some colleagues from across several functional areas of our shop to join me in refining the procedure. Together we presented the procedure to our management to continue to refine.

Alas, not all things can be done in a vacuum. Once we had a procedure that had buy-in across the shop and with our management, we had to pitch it to our customers.

We thought it wise to limit the release of the procedure to a single program. One of our newest customers was a missile program that was planning large batch orders. We asked if they would be willing to trial the new procedure on their products. After vetting the procedure with us, the missile program enthusiastically agreed.

With the initial trial complete and armed with concrete cost-savings and performance data, I asked my manager to go on an “antique road-show” of sorts where we presented the sample inspection procedure to every customer we served. This helped our customers become more comfortable with the change and that we were implementing it in a measured way.

After two months of the trial run and road show, we fully implemented the new process across all customer programs in or shop. Sample inspection ultimately resulted in a 50% increase in throughput while touch-labor hours remained constant.